Epoxy formulations have been an necessary portion of the constructing market for half a century. Epoxy floor coatings, in unique, are broadly-applied in floor applications. Here are some issues you may or could not however know about one of the most significant coating supplies in existence:

1. Epoxy resins are the secret behind high-performing epoxy coatings.

Epoxy resins are the core supplies of good quality formulations such as epoxy-based primers, prime-coats, and sealants. These resins make it possible for epoxy floor coatings to carry out nicely as floor finishes, protective coats, fire retardants, waterproofing and damage-resistance paints.

two. Epoxy coatings are applicable in many surface sorts.

Particular flooring applications have to have specific coating systems dictated mostly by the sort of material made use of for the substrate. Epoxy floor coatings are 1 of the few systems that can function in concrete, steel and practically all sorts of surfaces.

3. Epoxy resin molecules are cross-linked, hence they are nearly impermeable.

The distinctive chemistry amongst bisphenol A and epichlorohydrin organochlorine/epoxide compounds creates a reaction that produces cross-linked epoxies when exposed to amines. The resulting epoxy floor coatings are hugely-resistant to water, chemical or air intrusion — a critical capability in corrosion-prone metal or concrete surfaces.

four. Epoxies can combine with other supplies for enhanced functionality.

Epoxy-amine systems, epoxy-sulfide systems, aliphatic epoxy systems, and hybrid epoxy systems are some of the widespread coatings systems made in tandem with epoxy. With amine, glossy surface look, much better adhesion and quickly curing occasions are achieved. Epoxy coatings systems also perform nicely with alkyds and acrylics.

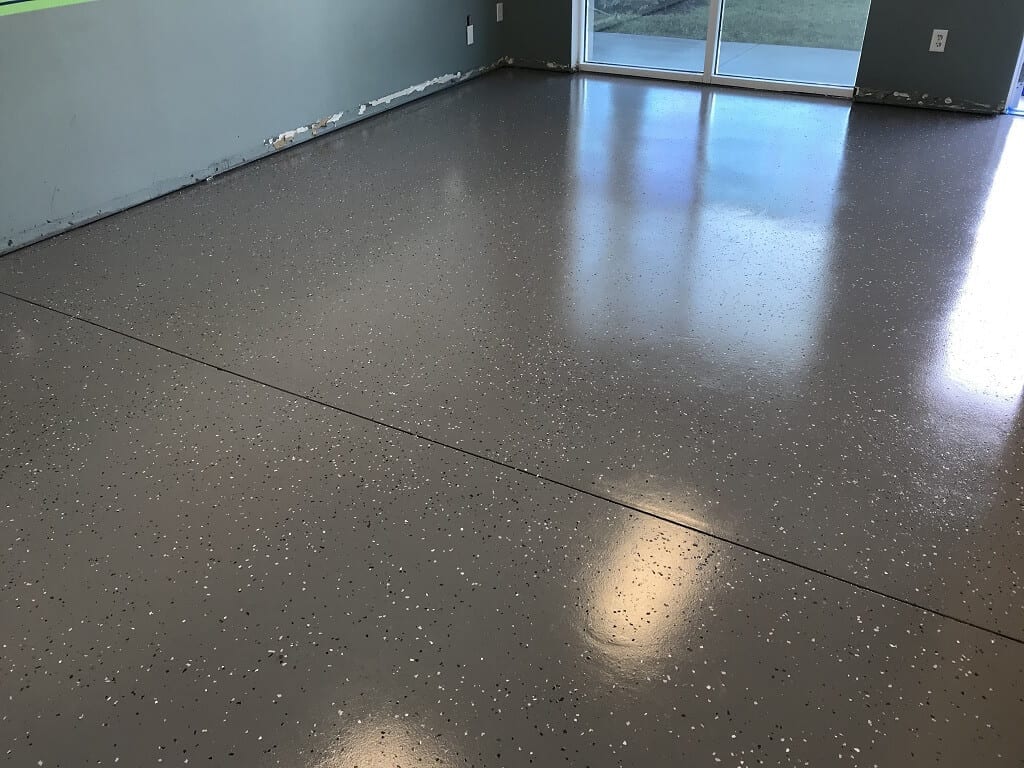

five. Epoxy floor coatings can protect heavy-duty floors.

Epoxy coatings are resistant to a lot of varieties of damages. No wonder that they are usually applied in areas that are consistently exposed to damage-inducing agents, such as in manufacturing plants, warehouse floors, heavy machinery garages and airplane hangars.

six. Epoxy coatings have impressive adhesive properties.

epoxy pebble stone floor Sherman tx -based coatings have sturdy adhesive capabilities — 1.5 thousand pounds of adhesive energy per inch square of flooring. This translates to floors that can stay intact and in good condition for longer periods of time and even beneath intense physical loads

7. Epoxy coatings are very good fire-retardants.

Some epoxy floor coatings contain pigments that expand promptly when exposed to intense heat. This expansion types a thick barrier protection that lasts lengthy adequate for the fire to be put out naturally or by a responding fire-fighting team.

8. Epoxy floor coatings are either water-borne, high-solids, or solvent-borne.

Water-borne epoxies are productive in many surfaces, whilst higher-solid formulations cover a wider application area and contain decrease VOC amounts. Solvent-borne epoxies are an older technologies but are high in VOCs and emit a toxic odor. The latter also needs a lot more remedy time and longer post-cleanup activities.

9. Epoxy floor coatings could contain overall health and environment hazards.

The bisphenol A compound in epoxy resins is presently under scrutiny as a potential well being hazard, and solvent-primarily based coats include higher levels of VOCs damaging to the atmosphere and to application workers.

10. Epoxy coatings have their share of vulnerabilities.

Epoxy floor coatings are really dependent on a constant mix ratio to steer clear of complications in the course of curing time. Applicators have to stick to manufacturer’s recommendations to keep consistency in texture and viscosity. The coatings are also unstable when exposed to UV rays and to temperature modifications in the course of the mixing, application and curing stages.

Epoxy floor coatings are high-performing and versatile because of the inherent chemical properties of epoxy. It remains to be 1 of the most sought-immediately after coatings systems that meet any sort of coatings application needs.

19 May, 2024

0 Comments

1 category

Category: Blog